When building a new home or undertaking a remodeling project in the Magic Valley area, you face numerous decisions, from selecting fixtures to planning electrical work. One crucial choice you’ll need to make is about your gas line options. Understanding these options is essential for ensuring your home’s safety, efficiency, and functionality. If you’re new to exploring gas lines, this guide will help you understand your choices and their strengths and weaknesses.

What to Consider

Before diving into the specifics of gas line options, it’s essential to consider several key factors that can influence your decision. The cost of gas lines can vary significantly based on factors such as the type of material and installation complexity. For instance, some types of gas lines may be more expensive to purchase and install due to their durability or the intricacy of the installation process.

The length and location of the gas line also play a crucial role in determining the overall project cost. Longer lines or those that require complex routing can increase expenses. Additionally, the gas line material’s flexibility and durability are important considerations, especially for repairs and remodeling projects. Other considerations include local building codes and maintenance costs. Understanding these factors can help you make an informed decision that balances cost, functionality, and long-term benefits.

The Most Common Gas Line Options

Typically, Idaho homeowners opt for one of four types of gas lines. They include lines made from black iron, corrugated stainless steel, galvanized steel, and high-density polyethylene.

Black Iron Gas Lines

Black iron is a traditional and widely used material for gas lines, and it is known for its strength and durability. It can handle high temperatures and is relatively straightforward to install. However, black iron gas lines are less flexible compared to other materials, which can make installation more challenging in complex setups. For instance, if you need to install gas lines in a kitchen with a complex layout, black iron pipes might not be the best choice. The rigid nature of black iron makes navigating tight spaces and corners difficult.

Another disadvantage of black iron gas lines is that issues can develop in the joints where the pipes are connected. These connections are sealed using thread sealants or pipe joint compounds to prevent gas leaks. Over time, these seals can degrade due to wear and tear, exposure to moisture, or other environmental factors. When the seal fails, it can lead to leaks or corrosion in the pipes.

Corrosion often starts at the joints where the seal has deteriorated due to age. If not addressed promptly, this can lead to more extensive damage, such as rusting pipes. Regular inspections are crucial to identify any issues with the seals and ensure that the gas line system remains airtight. If you choose to install black iron gas lines, you will have to have them annually inspected and occasionally resealed by a qualified professional.

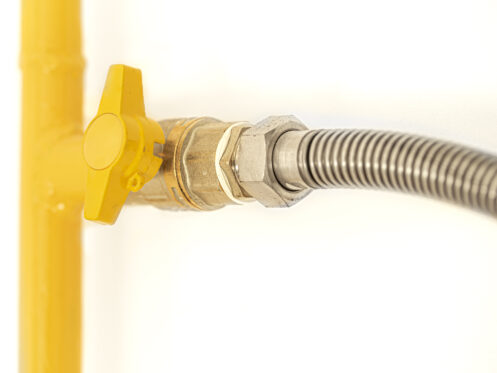

Corrugated Stainless Steel Flexible Tubing

Corrugated stainless steel flexible tubing is an excellent choice for installations in tight spaces or areas with complex layouts. Its flexibility allows it to be bent and maneuvered easily around obstacles, making it ideal for challenging installation scenarios. Additionally, this type of tubing is relatively affordable, which can be a significant advantage if you’re working with a tight budget. It also has a longer expected lifespan and requires less maintenance compared to black iron gas lines, primarily due to its corrosion resistance and flexibility.

However, while corrugated stainless steel is durable and resistant to damage, it is not without its drawbacks. Over time, the tubing can develop cracks. These cracks typically occur at the bends where the tubing is most stressed. Cracks can compromise the integrity of the tubing, potentially leading to leaks or other issues.

Galvanized Steel

Galvanized steel refers to steel that has been coated with a layer of zinc to protect it from rust and corrosion. This process involves dipping the steel into molten zinc, which forms a protective layer that helps prevent rust and decay. Galvanized steel is worth considering if you’re looking for a low-maintenance option for your gas line installation. It is extremely durable and resistant to corrosion, so you won’t have to worry about it deteriorating quickly. Although it costs a bit more upfront, the investment provides long-term peace of mind.

When installing galvanized steel gas lines, welding is necessary to create secure, airtight connections that can withstand the pressure and potential vibrations in the gas line system. This process ensures that the joints are robust and reliable, minimizing the risk of leaks. Due to the welding involved, the installation process can be more labor-intensive and time-consuming, so hiring a reputable and experienced professional is crucial for achieving a high-quality installation.

High-Density Polyethylene Piping

High-density polyethylene (HDPE) is a type of plastic made from petroleum that is known for its durability and flexibility. Manufacturers produce it through a process called polymerization, where ethylene molecules are chemically bonded together to form a dense, sturdy structure. This makes HDPE piping highly resistant to impact, cracking, and corrosion.

While HDPE piping offers many advantages, including resistance to corrosion and high flexibility, it is not always the preferred choice for all homeowners. One reason is that HDPE piping requires specialized fittings and tools for installation, which can increase the overall cost. Additionally, some local codes and regulations may not permit HDPE for certain applications, preferring more traditional materials. Lastly, although HDPE is durable, it can be more susceptible to damage from ultraviolet (UV) light, which may necessitate additional protective measures if you have it installed outside.

Considering Indoor or Outdoor Installation

Professionals may use different materials for indoor and outdoor applications to ensure optimal performance and longevity for your gas line system. For indoor applications, corrugated stainless steel flexible tubing or polyethylene piping is popular due to its flexibility and ease of installation. This material is well-suited for navigating complex configurations within your home. Alternatively, they may use galvanized steel or black iron outside or where additional strength is needed.

Spotting Gas Line Issues

No matter what materials your gas lines are constructed from, they will experience wear and tear over time. After your gas line installation, our Magic Electric, Plumbing, Heating + Air team can perform annual maintenance to ensure everything remains in optimal condition.

During a maintenance visit, our professional will thoroughly inspect your lines. This process includes checking for signs of leaks, corrosion, or damage. They will use specialized equipment, such as gas detectors, to identify potential leaks that might not be visible to the naked eye. Additionally, they will inspect the connections and fittings to ensure they are secure. If necessary, they will make adjustments or repairs to prevent future issues. Regular maintenance also reduces the risk of hazardous situations.

Contact the Pros

At Magic Electric, Plumbing, Heating + Air, we have been serving the residents of Magic Valley and the surrounding areas for years. In addition to gas line repair services, we install, repair, and maintain heating and cooling systems. We can also help with all your electrical and plumbing needs. Contact us today to schedule an appointment with one of our talented team members.